Here's what we do.

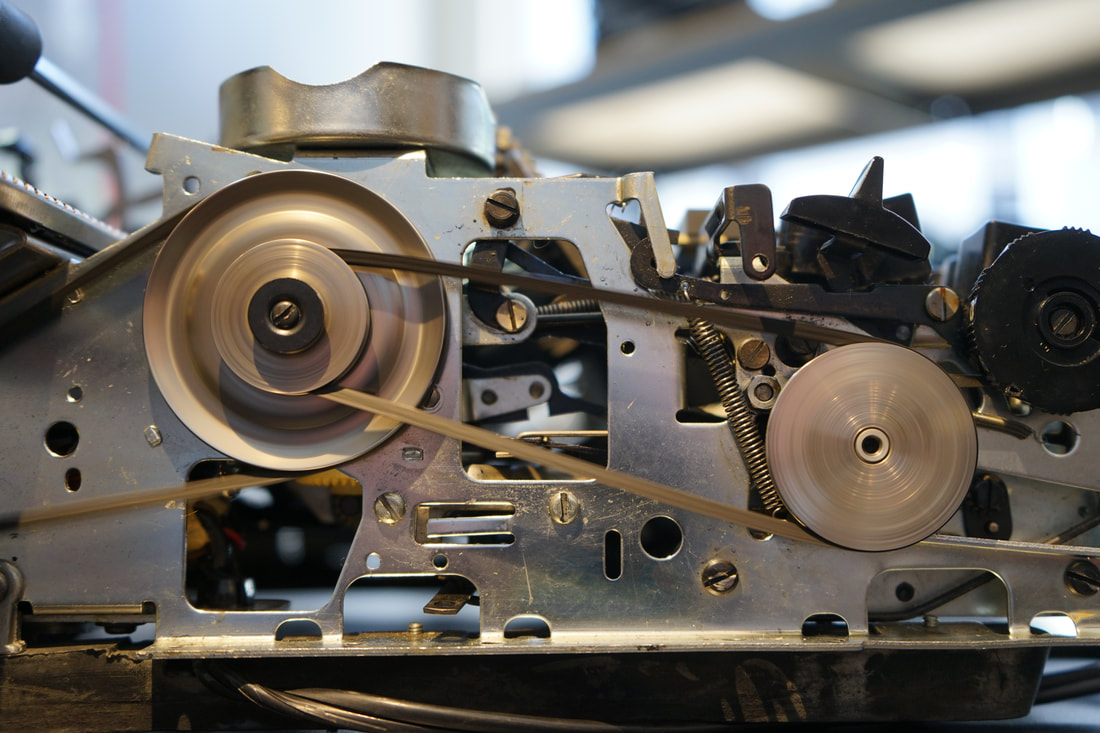

Once your typewriter has gone through our comprehensive and painstaking restoration process, you will be the proud owner of a functional piece of history. Our mechanics maintain a surgical level of care down to the last screw in order to bring your typewriter back to life. We pride ourselves in resurrecting these incredible machines, which is why all typewriters that we service or restore come with a 2-year warranty and a complimentary tune-up service at the end of each warranty year.

Meticulous DetailingSpecialists give painstaking attention to make sure every part of your typewriter shines, and is preserved for a new generation.

|

Old & NewWhether it's from the 1980s or 1880s, we'll bring your typewriter back to life. Cosmetically and full functioning.

|

Replacement PartsWe maintain an extensive collection of salvaged machines for replacement parts, as well as manufacture many of our own.

|

The first step is a thorough, in-person diagnostic inspection to determine what your typewriter needs. Once this is complete, our team begins what we call our "Culminative Care Process".

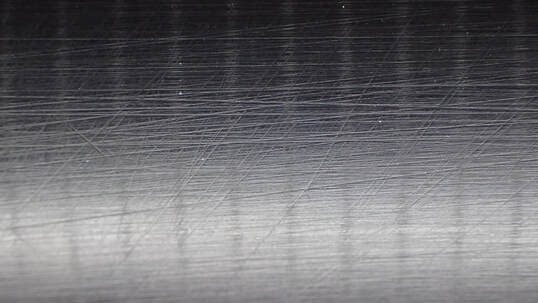

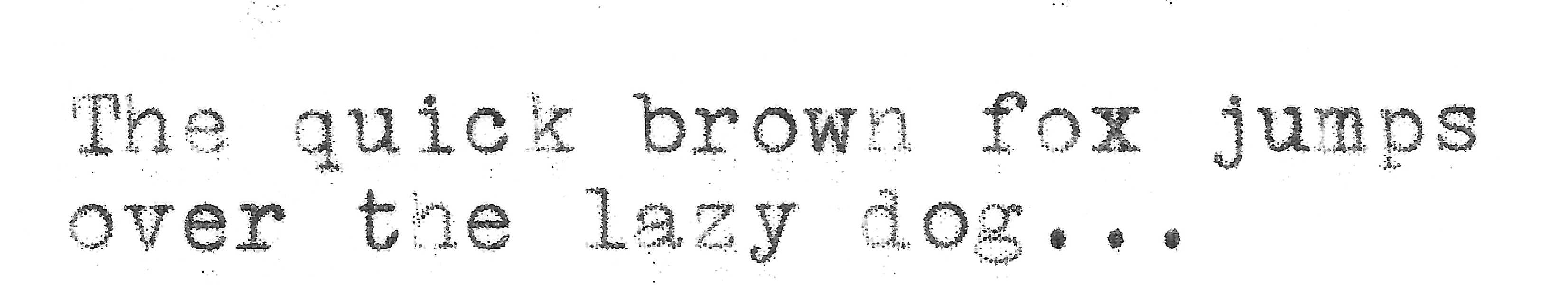

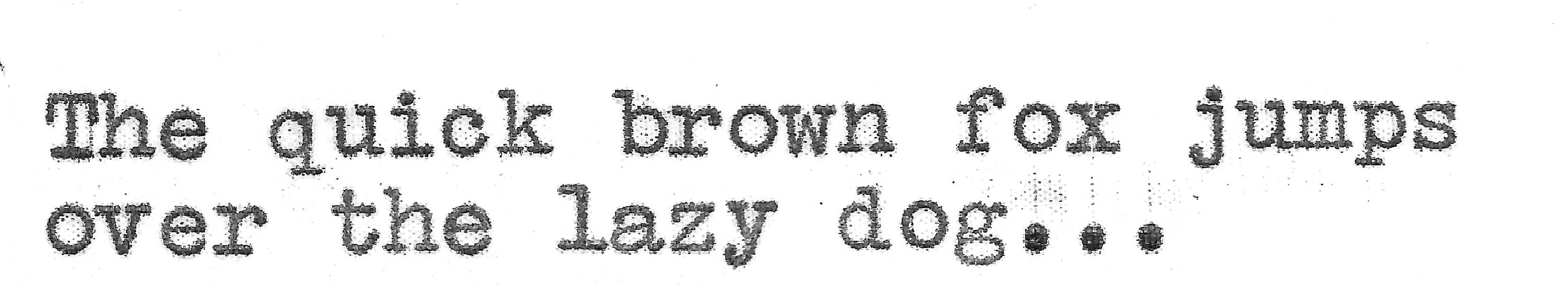

A new platen is a crucial part of every restoration. The new, soft rubber results in a clean and quiet typing experience. Replacing the platen also prevents substantial damage that can occur from typing on old, oxidized rubber, such as shattering the key slugs and causing misalignment. Fresh feed rollers are installed so the platen can firmly grip the paper. New feet are fabricated for the typewriter, which absorbs the vibrations that cause misalignment and keep the machine from sliding during use.

Look at the difference a new platen can make in your typing!

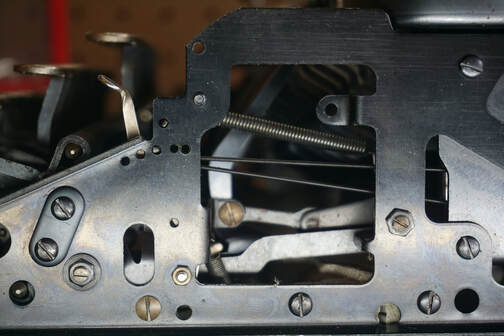

Each typewriter undergoes a top-to-bottom deep cleaning to remove decades of dust, debris, and solidified lubricants. Targeted corrosion treatments are used to remove rust. This restores the machine's original finish, loosens frozen mechanisms, and protects the typewriter from further corrosion. Once the typewriter is clean it is lubricated with fresh oil and grease.

|

Dozens of adjustments are made so that your typewriter performs exactly as it should. Improper adjustments can cause misaligned letters, function failures, and damage to internal mechanisms. Our team uses a combination of experience and historical research to make every adjustment as the manufacturer intended. Type bar alignment, scales, ribbon lifts, and shift mechanisms are just a few of the many adjustments we make.

With very few exceptions, there are no manufacturers of new typewriter parts. This makes our extensive collection of salvaged typewriters invaluable for replacing broken, faulty, and missing parts.

|

Our specialists install hand-cut insulation to keep your typewriter quiet and smooth. For some machines, felt stops are installed underneath the spacebar and paper guide for an extra level of cushion and protection.

|

|

Before a typewriter is ready to leave our shop it must go through final testing. Several mechanics will perform different tests, some of which are pulled from original manufacturer protocols. Our tests are rigorous and thorough because we want to be absolutely positive that your typewriter is suitable for continued, daily use. It's at this point that we decide the best ribbon fabric to use for the machine and install a new ink ribbon.

|

Ahhh... fresh insulation!

Detailing specialists use non-toxic cleaning solutions and polishes to make your typewriter shine. Hours upon hours are spent detailing the typewriter to restore the machine's luster. In addition to bringing the typewriter's beauty back, this process helps preserve the finish and chrome to prevent further deterioration. Special care is given to keep all decals intact.

|

Like any mechanical machine with hundreds of moving parts, a typewriter is meant to be routinely serviced every year or two. If you want your typewriter to last, it's important to bring it in for tune-ups. We're here for you when it's time to re-adjust and re-lubricate your machine so that it stays in tip-top shape. Our tune-up service is only available to customers who have had their typewriter restored by us.

Whatever mechanical typewriter you have, we are equipped and ready to restore it. Our mechanics and specialists are eager to revive your machine. We want you to leave our shop with a typewriter that works like it just rolled off the factory line. Once it's back on your desktop, rest assured that you've rescued a piece of history and preserved it for generations to come.