We service, overhaul and manufacture parts for Selectrics that are used by businesses on a daily basis and those that have been sitting in basements for decades. Whether you're looking to keep your office machine running, resurrect a neglected Selectric, or if you're a newcomer and looking to buy, we're here for you. All Selectrics that we service or sell come with a five-year warranty and a complimentary tune-up service at the end of the first, third and fifth year. Not just that, but we'll take care of your cartridges and, if needed, correction ribbons, for the first two years.

We stand by our work because IBM could stand by theirs. Make an investment in your writing, your business and your future with the IBM Selectric.

We stand by our work because IBM could stand by theirs. Make an investment in your writing, your business and your future with the IBM Selectric.

The IBM Selectric is a machine unlike any other. Compared to the typewriters that preceded it and the word processors that followed, there is nothing that comes close to the Selectric’s combination of speed, precision, durability, and function. They’re easy to use and practical for home and office work. These machines are not meant to be thrown away for the next new thing. Maintaining a lifespan that simply does not exist in modern technology, Selectrics are meant to endure, and we have the expertise and the facility to work on the 2,800+ parts that make up the machine.

|

All of the high-mortality components are replaced with brand new parts that we manufacture to ensure your Selectric will endure. Both the cycle shaft and operational shaft are rebuilt with new gears and clutches. These high-mortality components and others, such as our newly manufactured Selectric hubs, can be found for individual sale on our Parts Manufacturing page. These hubs come with a lifetime warranty against manufacture defects!

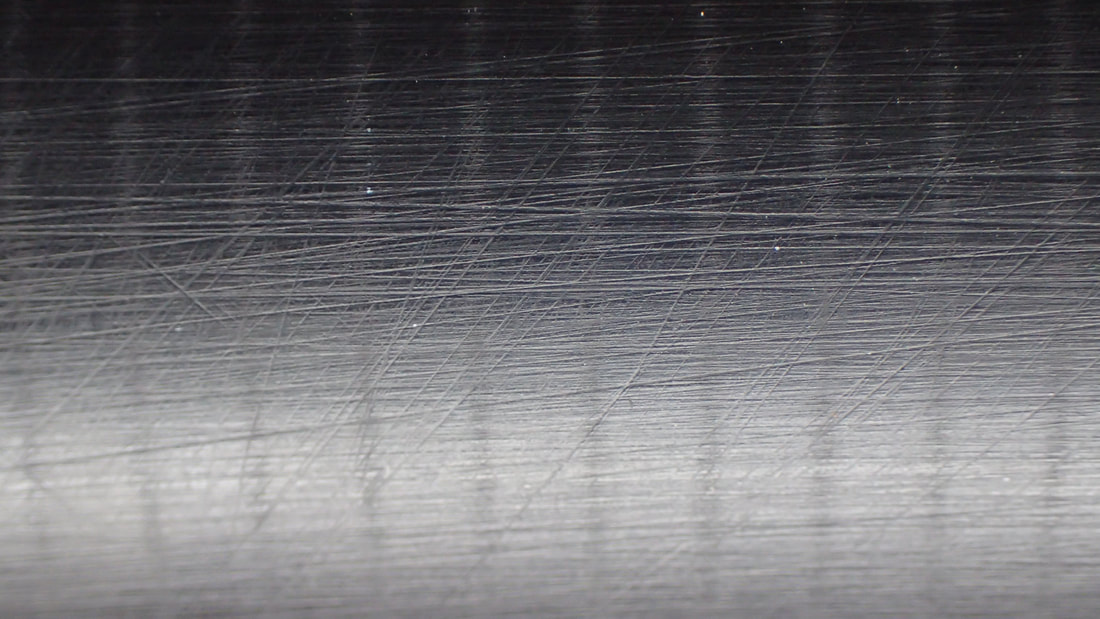

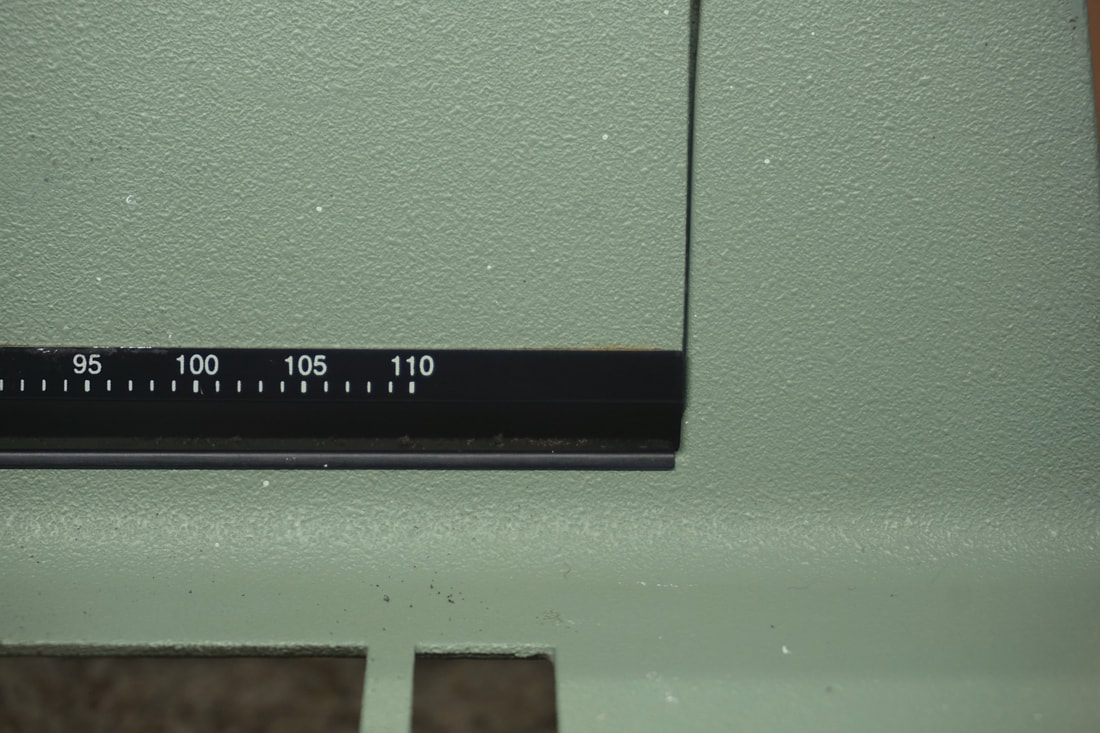

For a machine as precise as the Selectric, proper adjustments are vital for optimal performance. Whether it’s the carriage return shoes or the homing position, every adjustment is exactly as it should be. In addition to the chemical cleaning inside the machine, each Selectric undergoes extensive cosmetic detailing. From the body to the levers to the key tops, your Selectric will shine. |

The Selectric is chemically cleaned to address the decades of debris and solidified lubricants. Machines that have been sitting for a while require painstaking deep cleaning, which involves individually freeing up hundreds of coagulated parts. Once the Selectric is clean and freshly lubricated, we’re able to begin an extensive diagnostics process to identify any problems the machine is having.

|

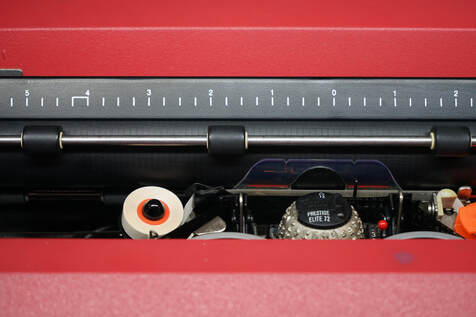

Fresh rubber parts are important to any typewriter but especially so for Selectrics. A new, soft rubber platen is crucial for the type element to produce quality print and for the correcting tape to properly lift off typed characters. New platens are fabricated and installed for optimal performance and to prevent hard rubber from damaging the machine. Feed rollers are refinished or replaced to ensure that the platen smoothly grips the paper.

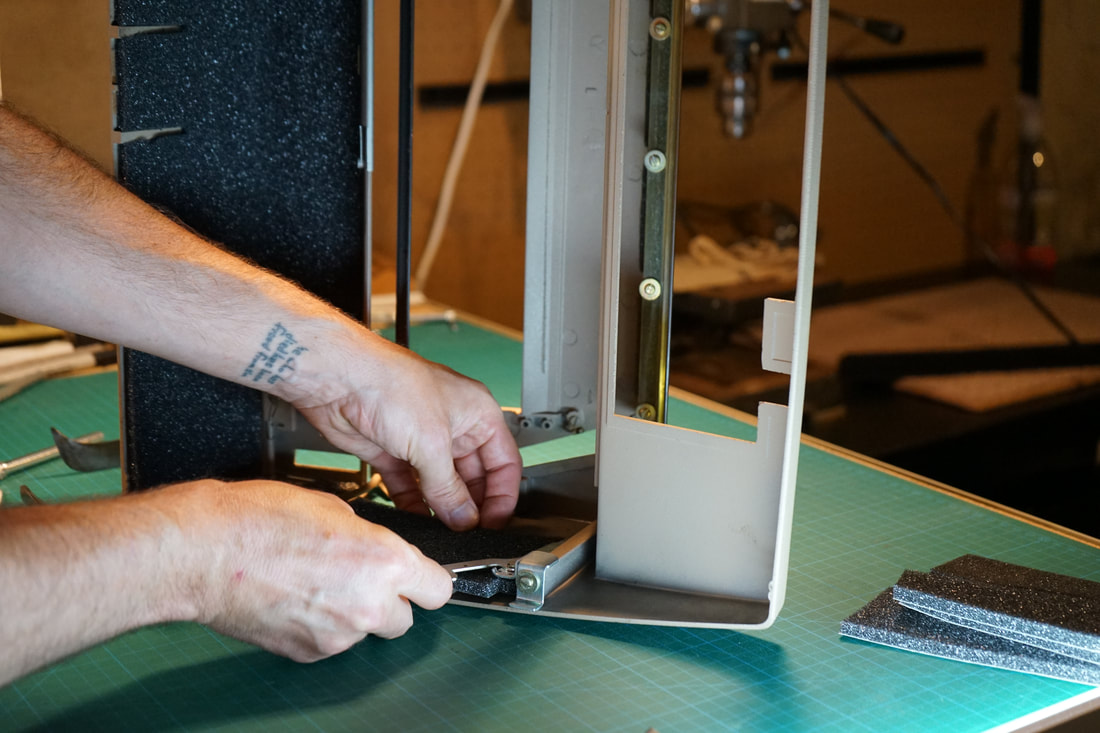

Over time, the original body insulation and keyboard matting disintegrates and falls into the intricate internal mechanisms, resulting in a loud, rough machine prone to mechanical failures. All of the old foam is removed and new hand-cut insulation desgined and enchanced from IBMs original design is installed to dampen noise and reduce vibration.

|

|

|

If you're looking to buy a Selectric, choose from multiple colors we have available.

Not seeing the color you're looking for? Although we specialize in the preservation of these machines, it's important for us that a typewriter and their owner click. For specific machines, including the IBM Selectric, we offer our clients a wide range of colors and textures with our custom powder coating options!

At the very end of a service, each Selectric goes through rigorous testing. We don't stop work until the machine performs up to factory standards. Once we’ve completed a service on a Selectric, we’re here for ongoing maintenance and tune-ups.

When it comes time to replace the ribbon or correcting tape, we have the supplies you’ll need. If you have a question about how to use a particular feature, we’re only a phone call away. We're here with you, for the long run.

When it comes time to replace the ribbon or correcting tape, we have the supplies you’ll need. If you have a question about how to use a particular feature, we’re only a phone call away. We're here with you, for the long run.